Bonded sheet fluoropolymer linings are available in PVDF, ECTFE (Halar), ETFE, FEP and PFA utilising fabric backed fluoropolymer sheet laminate and Plastichem’s unique in-house developed vacuum bonding techniques enabling operation at elevated temperatures and vacuum operating conditions. Thermoplastic linings are also available in Polypropylene and Polyethylene.

Lining Techniques

The surface of the item to be lined is firstly prepared by grit or shot-blasting to SA2.5 or higher and to the recommended surface roughness.

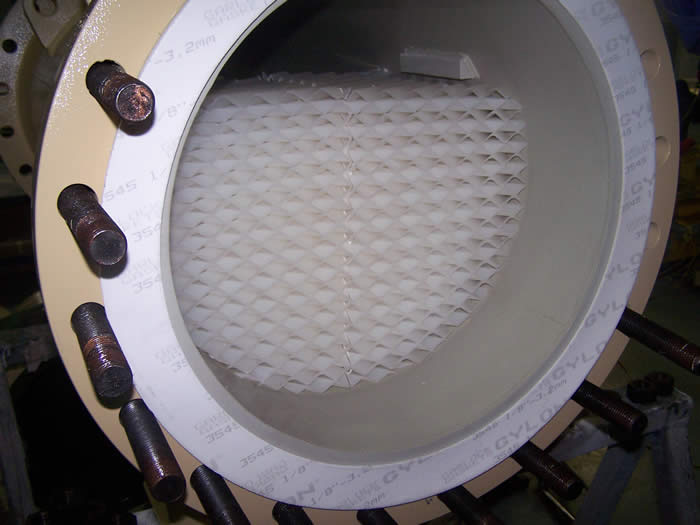

The lining panels are thermoformed where necessary and body panels factory butt welded where practical to minimise hot gas welding operations. The lining is then vacuum-bonded and any joints fusion welded to create a continuous lining.

To prove the essential integrity of the lining a non-destructive test especially developed by and unique to Plastichem capable of detecting partially fused welds is carried out on all welding. This is followed by the standard NDT testing of the complete lining utilising a high voltage spark test.

Temperature Resistance of Bonded Fluoropolymer Linings

As a general guide the maximum temperature limits apply due to the properties of the bonding resins:-

| PFA Lining | 140 Deg C |

| FEP Lining | 135 Deg C |

| PVDF Lining | 110 Deg C |

| ECTFE Lining | 110 Deg C |

To utilise the maximum temperature performances of FEP, PFA and PTFE, un-bonded or mechanically fixed linings should be considered.

As well as vessels, typical lining applications also include :

Road transport vessels and ISO Tank containers

Columns and column internals

Dip pipes

Manway covers

Ducting

For more information on our bonded sheet linings, please call us on 01706 712525 or complete our contact form