GRP or FRP pipework is manufactured in accordance with BS 7159, with structural, chemical and thermal properties being dictated by the type of resin selected by Plastichem specialists.

GRE pipe systems with filiament wound construction provide higher mechanical strength with lower cost.

The most common resin type specified is a Vinylester Epoxy which has excellent chemical resistance to a broad range of chemicals.

Plastichem design experts can offer stress analysis on all GRP pipework. Stresses are reduced where necessary by increasing laminate thicknesses, increasing leg lengths and adjusting support distances and clamp positions.

The internal corrosion barrier can be varied to suit the application and abrasion resistant GRP linings are also available for flue gas slurry handling.

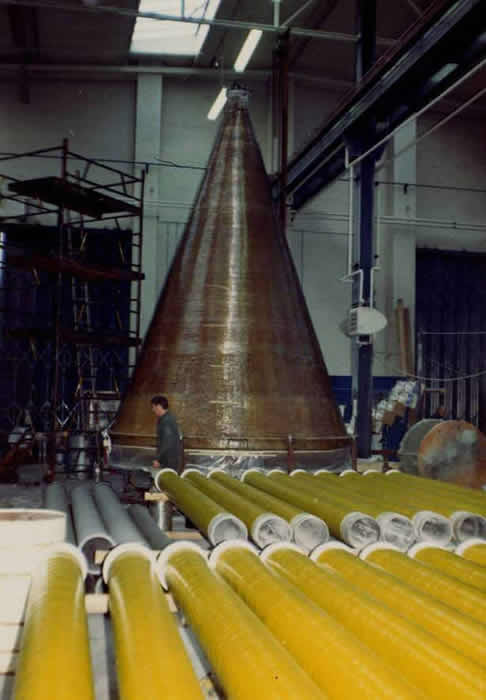

Manufacture of the pipe is by mandrell winding of chopped strand glass fibre or by filament winding. Elbow and tee fittings are moulded and then joined to the pipe where required.

One of the benefits of this system is that sections can be pre-fabricated in the factory and then site joined. This method minimises site work and elliminates flanged joint connections.

GRP piping can be coloured externally for line identification, UV and fire resistant properties can be enhanced with additional resin coats.